Hotel Kitchen Design Guide

Designing a hotel kitchen goes way beyond the replacement of kitchen equipment, and there are so many important considerations to take into account.

Over the years, we have had the privilege of working with a wide range of hotel clients, from world-famous five-star hotels in London with Michelin-star restaurants to large adult-break hotels in the countryside that focus on buffet dining. Many of these kitchen projects have gone on to win awards for both kitchen design and project management.

This blog will explore some key considerations about hotel kitchen design. Whether it’s a refurbishment of your existing kitchen to make it more efficient, or a brand-new hotel kitchen installation.

In This Blog, We Will Cover:

- Kitchen Design Uses

- Kitchen Design Efficiency

- Kitchen Design Environment

- Kitchen Design Equipment

- Energy Management Solutions

- Trends

- Client ROI Example

Click the links above to learn more. And if you need assistance click here to contact us!

What Do Hotel Kitchens Have to Accommodate?

Hotel kitchens are complex food service operations, often balancing a variety of accommodations including:

- In-room dining/room service

- Breakfast

- All-day dining

- Dinner

- Fine-dining or Speciality Restaurants

- Functions & banqueting such as Awards ceremonies, conferences & weddings

- Catered events such as weddings

Need help with planning your hotel kitchen?

We know that efficiency, cost savings and sustainability are high on everyone’s agenda. That’s why the efficiency of a hotel kitchen is the primary consideration when starting work on a new project. The requirements of a hotel kitchen will need to be identified before we can begin working on drawings or even sketches.

It is also essential that hotels offer unique menus, catering for all dietary requirements, and dining experiences to draw in customers who are not staying in the hotel.

In some hotels, there will be one central kitchen that is then divided into smaller specially designed sections for the food services being offered.

For example, the 5* Park Lane kitchen project that we designed includes areas for in-room dining, breakfast, banqueting and even a chef’s table experience catering for just 16 diners. This meant that the ergonomics of the space were crucial in it working effectively in a combined kitchen area.

Creating a better workflow for your operation, will increase your brigade’s efficiency and in some cases, reduce the number of chefs you need at any one time.

If you operate 24 hours and 7 days a week, all designs suggested for the kitchen must allow for maintenance and repairs to be carried out without any major disruption caused by engineers.

For example, kitchen equipment should be positioned into the design without the need for it to be pulled out, and multi-use appropriate equipment considered so that it enables flexibility if a certain piece of equipment is being worked on.

Did you know that we have engineers who start, on-site, at 5 am, all of whom have adapted to the hotel’s way of life to ensure your maintenance and repairs are done with as little disruption as possible?

We have demonstrated that our award-winning hotel kitchen designs can provide a full return on investment within three to four years based on reduced energy consumption alone. This is based on intelligent, ergonomic designs and the application of energy-saving equipment and monitoring systems.

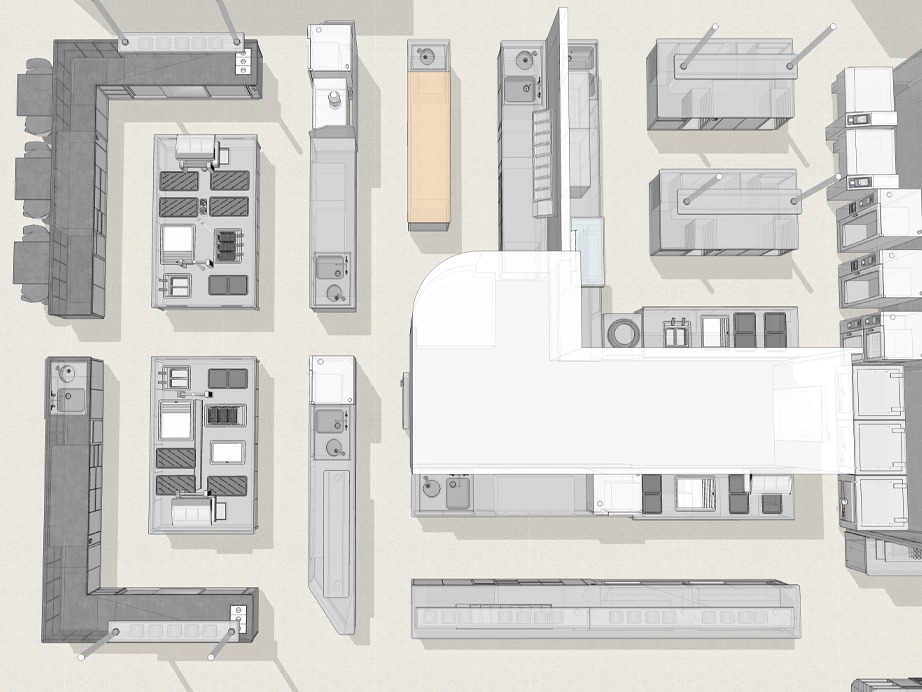

We provide our clients with initial 3D visualizations to give them a general sense of the space’s aesthetics and ergonomics. This is critical because it ensures that the client understands the flow of the space from the start, rather than simply knowing where the equipment will be located. This allows you to visualise how your cooking stations will operate, where your storage space will be located and if there is sufficient space allocated for food prep areas.

Once the client is satisfied with the initial drawings, we provide them with 3D-rendered visuals and walkthroughs created in Revit. This maximizes the use of space by considering all of the details and visualizing them, which is especially important in city hotels, which typically have limited kitchen space. This allows us to use BIM models and provide a comprehensive itemized quote. The result being commercial catering kitchens that are not just functional, but pleasant working environments expertly designed to maximise your available space.

This leads to a much deeper understanding of how the kitchen is intended to function and what hotel kitchen equipment design layout and details best meet the needs of the operator and chef.

- Heavy Duty Bespoke Fabrication – Good kitchen hygiene is vital for the safety of staff and guests beyond this adhering to the UK’s health and safety standards is a legal requirement. Bespoke fabrication ensures that hygiene is considered from the outset of your project. From creating fully seamless food preparation and cooking areas, to cook suites and modular equipment with one-piece tops and plinthed flooring. These all help to prevent food traps, dirt and fluid ingress. Raising your equipment, such as the cook suite or preparation counters, onto a plinth with the flooring coved up will remove any risk of poor hygiene under equipment.

- Induction – Induction creates a better working environment because temperatures and noise within the kitchen are lowered. Reduced energy consumption is also achieved as the appliance needs no preheating and the hobs are only on when the pan is in contact with the cooking surface. The instant heat provides more than 50% of a standard hob which is perfect for late-night food orders for in-room dining. This helps to drastically reduce running costs by 70% and cleaning by 90% as the equipment only needs soapy water rather than chemicals which can be a major cause of damage to equipment.

- Multi-Use Equipment – Amazing for hotels with small kitchen layouts, but larger kitchens can reap the benefits. For example, the Rational two pan iVario gives you the flexibility for a combination of frying, deep-frying, sous vide, boiling and confit. The iVario also allows you to pressure cooking or slow cooking food, which is ideal for overnight savings in labour and time. Multi-use equipment enables you to cook various items on your menu without specific equipment that takes up space but is only used occasionally.

- Granular Pot Wash Machines – This helps to reduce running costs and wastage as well as improve cleaning results and working conditions. They use less energy to operate, despite the additional electrical load. This is due to using less water and chemicals to operate, combined with less staff. With the inclusion of thousands of plastic beads that fire at the pots and pans, all dirt and grease are loosened allowing the cleaning chemicals to fully work, giving perfect results every time. This all prevents the need for pre-soaking and scrubbing before going into the machine.

- Remote Refrigeration Pack Systems – While remote refrigeration pack systems can initially cost more, they are more energy efficient, reduce maintenance costs, save space and heat within the kitchen, and increase refrigeration capacity or capacity for additional catering equipment. This system is more reliable, this is because all the refrigeration is controlled by one centralised “pack”. Within the pack, you have two compressors, meaning if one compressor is down or faulty, your refrigeration will not fail as it will still be able to run off the other compressor.

- Combi Ovens for Functions – Having a combi oven in your kitchen will allow you to cater for more covers, even when you can’t expand your kitchen footprint. They provide you with more flexible cooking, and convenience and consolidate your equipment. If you are on the hunt for a new Combi Oven, we can help you through the entire process. We can even help when it gets around to servicing your equipment with fully trained engineers on most manufacturers’ equipment.

Read our in-depth blog to learn more.

Energy Management Solutions

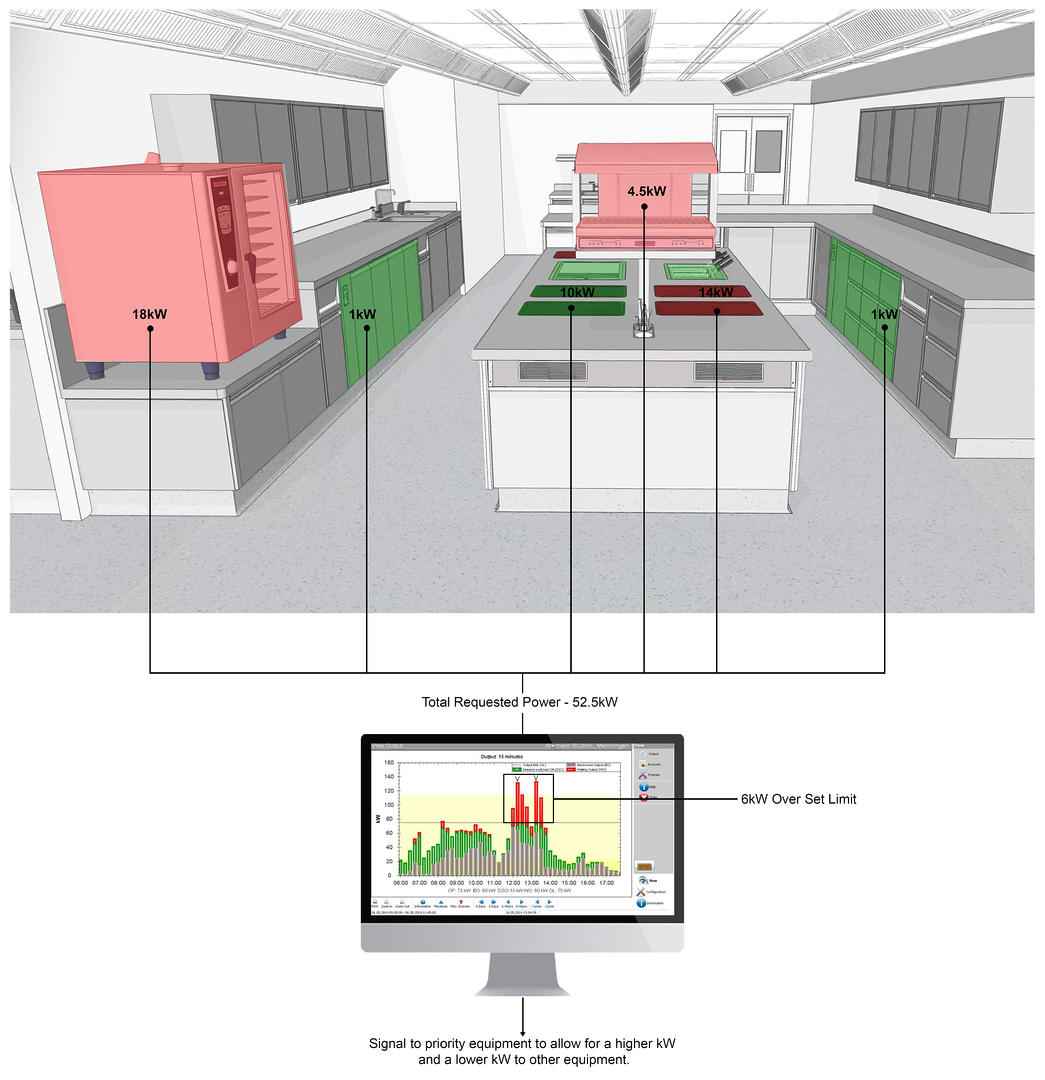

There are two principal solutions available on the market which can help reduce the connected load of your catering equipment, whilst managing your energy consumption.

The innovative solutions work by managing your kitchen’s electrical demand to ensure that the peak power load is never exceeded. By constantly monitoring the on/off and thermostat status of each appliance’s heating, power usage, connected load and idle phases, the system can evaluate and optimise according to the preset parameters.

For example, equipment that requires lower usage such as pasta boiler or fryer can have its power limited, with high requirement equipment such as induction tops or a combi oven having full power.

There is also an energy management solution that can just be applied to the cook suite, giving you fingertip management from any connected device. This is an ideal solution where power supply within the building is an issue.

We have been providing energy management solutions for over 10 years, helping to reduce your energy consumption, save costs and improve the well-being of your kitchen brigade.

Commercial Kitchen Layout Trends

With the rise of food tourism, hotels are more than just offering guests a room. They have become masters in offering a mixture of cuisines to complete the overall experience. Guests and customers are looking for something unique, they are looking for variety, and they are looking to be matched to the perfect dish in a hotel restaurant.

One popular trend is to open hotel commercial kitchens to give diners a more theatrical experience. The reduction in the amount of heat produced through the use of induction, alongside improvements in fan technology has enabled hotel restaurants to become a more inviting environment. This means you can invite guests into the spacing, and add drama to the dining experience, especially where chefs are working with charcoal ovens and pizza ovens!

The additional advantage of a theatre-style kitchen is that it shows diners the food being freshly prepared and freshly cooked, giving them more confidence in your menu.

Chef’s Tables are becoming increasingly popular as part of providing a more interactive experience. Part of our redesign for a 5* London hotel was the inclusion of a private client room with a panorama window overlooking the kitchen, adding to the exclusive feel of private events held at the Chef’s Table and giving the hotel an additional revenue stream.

Example Client Energy and CO2 Savings

For every major project we deliver, we provide our clients with financial, energy, and CO2 emission return-on-investment information. This is to help illustrate the financial and environmental impact their new kitchen could have. Below is one such example of savings a client has made.

An estimated

£845k

total savings over 10 years.

An estimated

1,213 kWh

saved per day.

An estimated

97 Tonnes

CO2 saved per year.

Based on induction, energy management and remote refrigeration systems!

This is equivalent to the average consumption of 152 homes using 8 kWh of electricity per day!

This is the equivalent to 7.6 cars driving 23,000 miles each (that’s once around the world!)

Start your hotel kitchen design journey…

Over the years, we have had the privilege of working with world-renowned five-star hotels for all of their kitchen design and installation requirements.

Many of these designs have gone on to win industry-recognised awards, save our clients significant running costs and provide a true return on investment.

If you’re looking to review your hotel kitchen design, or looking at a brand new project, we’d be happy to help! Get in touch below!