About the Cedar Kitchen at The Grove

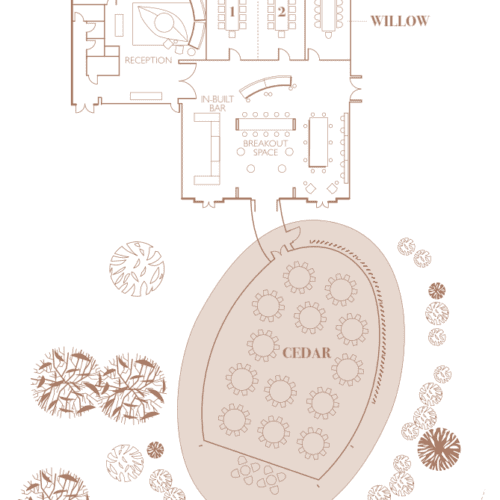

The Grove is a 5 Star Hotel and Spa with various restaurants. We worked directly with the owner to deliver the project. The client’s project was to turn a bedroom and store area into a banquet kitchen and create a new 200 cover function room from a patio area.

To enable the installation to take place without disturbing the guests, and ensure a fast, concise, program we had to come up with a carefully defined strategy before the project started. We undertook six months of very detailed planning to cover any uncertainty… with hotels events can change hourly!

The Brief

As you’d expect from a five star hotel and restaurant, the brief was very detailed and specific. The new kitchen had to be designed to the following brief:

- The food produced needed to be the highest quality. With fine dining on a large scale, the speed of kitchen to table and efficiency was paramount.

- We had to overcome the challenge of limited access to the kitchen. There was only one specific route in and out due to the available corridor, so getting the correct ergonomics was key to the brief.

- Create/incorporate a dedicated stills area and wash up space to also be used by other kitchens and prevent corridors becoming congested.

- Segments of the Cookline needed to be used alone or altogether, giving maximum flexibility to cater for any size function

- Provide a design with electric equipment only; demonstrate the longevity of the design and energy savings.

- The facility must be able to cater for increasing numbers of different dietary requirements including vegetarian, nut free, gluten free and small order menus.

- Use lockable storage cupboards so contract caterers can use the kitchen with access only to certain parts, providing flexibility and additional revenue stream.

- The design had to be flexible and scalable, work equally well for contract caterers and varied sized functions, allowing segments of the Cookline to be used alone or altogether, preventing waste and increasing flexibility.

The Chef Brigade at the Grove Hotel in Hertfordshire needed some help with designing and budgeting for an additional sending kitchen to cater for some special customers and to deal with a few bespoke clients and to be able to deliver up to 200 in banqueting. We told TAG what our expectation were and what sort of equipment we needed and to be honest knowing there was not a lot of room to work with. The TAG team come up with a few suggestions that we worked through.

We eventually came up with the right fit that was going to work within budget, the “WOW” for me and one of the main advantages during our discussions was that Tyron could put my some of my thoughts down onto a 3D CAD that I could actually visualise and understand how it was going to work.

A great team effort, they are with you and supporting you all the way and on the ball for any snagging bits. A brilliant addition to our Banqueting suite. Highly recommended

The Solution

The installation was within a working hotel with prestigious guests, so noise and working times were very limited, and the appearance of the site hugely important. Careful programing was required with noisy works and deliveries at fixed times in order for guests to remain undisturbed, or even notice work was taking place. These plans were reviewed every morning.

In addition, during installation the Hotel was host to the England Football team training for the Euros. Consequently, certain areas were closed for periods and we had noise restrictions which prevented us from unhindered work programmes. Obviously we wanted to make sure England had the best chance at the Euros by not causing any issues!

Working around the England football team also made equipment moves critical. We had to undertake noisy work when the team was on the field training, and moves had to coincide with meal times. We therefore had to coordinate with the F&B staff and the team training staff; our operations staff were equipped with radios in order to allow them to stay informed, so we had time to clear the public areas.

The equipment specified was selected to give maximum performance/cu meter and output as space was a premium:

- Frima 211+ bratt pan to reduce the amount of equipment needed within the finishing kitchen.

- Rational Ovens: 202, 102, 62 with the capacity to cover a full function, or be used stand alone for smaller functions.

- The Double Hood Meiko Dishwasher to cope with capacity efficiently.

- Floor to ceiling dry storage cupboards.

- Compartmentalised ‘areas’ that allow staff to work efficiently and ergonomically.

The Banquet room was a new-build using an old patio area, two metres lower than the kitchen itself making access from one area to the other a design dilemma to overcome. The available space was awkward, long and narrow with one access point at the end. After many test options, the solution was a curved access corridor at a low enough angle to allow safe, smooth transportation of trollies from kitchen to function room; finishing right at the entrance to the function room behind a drop wire screen, perfect for both service and access to the bespoke designed bar and rest areas for bar food and cinema screenings. An interesting project, it needed a complete re-think of standard banquet kitchen design.

The Outcome

Banquet kitchens are often overlooked and considered functional and uninspiring rather than award winning. However, this project demonstrates with careful design and innovation a truly exceptional design can eliminate service issues and provide not only good working conditions, but also overcome major logistical and structural limitations, which need to be seen to be fully appreciated. The resulting banquet kitchen produces large scale fine dining as opposed to traditional standard banqueting.

We rethought how a banquet kitchen operates and delivered a kitchen that is both functional, flexible and in an area that others would not have considered feasible; we used the most up-to-date banqueting equipment to maximize efficiency further. Consequently only a small amount of equipment was needed to cater for 200+ covers. Catering Teams and both small and large functions can be accommodated easily for all menu types to the highest standards too.

Factor in the installation challenges we overcame, such as the residing England Football Team, and how happy the client was with the result, made this an award winning project.

The coordination between TAG and the main contractor was very good and the installation process was delivered with the flexibility that is always needed with a new build project. The end solution is a very effective and workable finishing kitchen and service area.